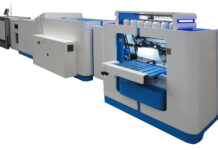

The Vivid Laminating Technology Ltd. 20 metre-per-minute Matrix MX-530S, along with an Omni-Flow Deep Pile Auto Feeder at Hughes Print, has increased overall operational efficiencies since its installation.

Hughes already had a Matrix MX-530P and were impressed by the quality and consistency of its output. When it came to increasing their in-house capacity they looked to Vivid for a solution. The faster speed and heavier construction of the MX-530S combined with the Omni-Flow Deep Pile Feeder has meant that a 2000 SRA2 sheet run or greater is now viable in-house.

Proprietor Dan Hughes said, ‘The extra production speed and semi-attended operating means that we are now a lot more competitive on products produced on this system. The 530S builds on the foundations of the 530P system; it is able to handle all of the existing laminate and foil work we produced on the 530P and with the Omni-Flow at a much faster rate. The laminate and foiling finish on both machines is excellent. We are hopeful that this side of the business, with the increased productivity, will allow us to handle larger jobs on this equipment.’

The laminators support Hughes’ digital print station on short run lamination and foiling work and their full colour litho press, primarily on booklet covers. The addition of the Flat Book option on the Matrix additionally gives Hughes an edge on PUR perfect binding jobs.

The new 20m/minute system was installed by Vivid staff who also supplied comprehensive training to the Hughes team on-site. Features such as pneumatic rollers and stabilised temperature control ensure consistent results across long runs and repeatability on re-runs, reducing waste and saving time and money.