Kodak will showcase its powerful and productive portfolio of digital print and packaging solutions at Grafitalia 2013, taking place from 7-11 May in Milan.

Stimulating sight and touch will be the emphasis of Kodak’s portfolio focus, while experts will be on hand to talk about how the solutions can help expand services and win business by adding value and creating stronger customer relationships.

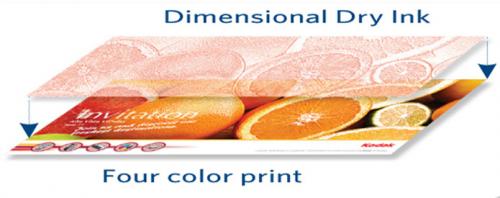

First to grab the attention of visitors to Kodak’s stand F21G24 in Hall 1 will be the array of finishes achieved by the KODAK NEXPRESS Fifth Imaging Unit Solutions on the KODAK NEXPRESS Digital Production Color Press. Capable of adding spot colors, gold* and pearlescent* effects as well as Kodak’s unique in-line dimensional printing, high-quality gloss, in-line watermarking, or coating in a single pass, the application helps printers differentiate themselves in a highly competitive market.

The KODAK NEXPRESS Digital Production Color Press also keeps apace with the latest market demands and developments by increasing the production page size to 914 mm. This opens up new markets possibilities – particularly for panoramic publications.

On the booth, there will be two workflow stations, featuring the new KODAK PRINERGY Workflow System Version 6, running live demos showcasing customizable automation, thirdparty integration and unified job management for the print production and manufacturing process. The PRINERGY Workflow System will be integrated with the KODAK INSITE Prepress Portal System to highlight how secure web access for customers, prepress operators and service reps supports their remote job submission, progress tracking, collaboration, remote proofing and approval cycle times.

Visitors can equally get informed on the KODAK SONORA XP Process Free Plates that completely eliminate all costs associated with processing equipment and chemistry, while requiring less floor space and reducing energy consumption— all great for reducing the environmental footprint of printing, but even better for its bottom line. Offering high-quality thermal imaging and the complete elimination of plate processing, SONORA XP Plates increase productivity, simplify operations, and remove costs by reducing the number of steps required for platemaking.

A focus on hybrid printing with the KODAK PROSPER S-Series Imprinting Systems, will detail the profitable production process being adopted by many European printers for various commercial projects including direct mail, inserts, games, advertisements and labels for packaging. Running at 152mpm and with high image quality, KODAK PROSPER S5 Imprinting System lowers the entry point into hybrid printing. It is fully field upgradable so customers can increase their capabilities when demand requires. Videos and explanatory models of real systems will highlight the technology’s potential and how it can help operations with their future growth.

*The capability of adding gold* and pearlescent* effects is not yet commercially available. Currently available for demonstration purposes only.