Hunkeler will show a diverse range of digital production feeding and finishing solutions at drupa. Twenty lines comprised of more than 85 modules will be shown in 14 partner booths in 10 halls. With its comprehensive presence in partner booths and in Hall 9 (formerly Hall 14), the company confirms its position as the leading provider of pre and post solutions in the fast growing digital print market.

Book-on-demand solution – flexible, high performance

The digital book solution with its new double star wheel delivery and the PF7 Double Plow Folder produces book blocks with 4, 6 or 8-page signatures in non-stop operation, reaching an output of 200m per minute (653 fpm). The book-on-demand line has a capacity of more than 450 output cycles per hour. As part of each cycle, several book blocks are delivered in stacks. At a speed of 200m per minute and 4-panel production, this amounts to 2245 Books per hour with a length of 192 pages each. Integrated book block gluing facilitates secure handling for near-line perfect binding.

Modular planning and control system

The Hunkeler Control Solution presents a modular solution for planning, control and monitoring of production processes. The system is based on five conceptual stages: Mail Tracker as the entry-level solution for everything to do with product recording and tracking; Print Processor for production preparation; Workflow Monitor for quality control; Site Manager for centralized, time and location-independent process supervision; and Production Reporter for recording and quality verification.

Safety laser cutting with Hunkeler finishing

As a technology demonstration, Hunkeler is presenting a unique laser-based punching and perforating system for security printing. Checks, coupons or mailings can be individually and distinctly marked or engraved with any punching or perforating pattern at previously unreached outputs of 150m per minute (492 fpm). The Web Inspection System WI6 is used for in-line verification of the security patterns.

Large sheet stacker with digital roll printer

A new solution for production from the roll to digitally printed large format sheets which supports sheet-fed offset printers in the initial stages of digital print. Existing processing technology can be used in combination with the new system. Using the Unwinding Module UW7, the paper web is fed to the cross and longitudinal Cutting Module CS7. The large format stacker LS7 takes cut sheets up to format sizes 1100 X 760mm (43 x 30) and stacks them up to a pile height of 800mm (31). The stacker is integrated into the overall Hunkeler system and is currently available.

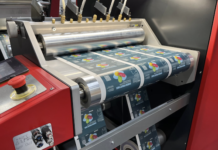

Complete paper conditioning or refinement

The Primer Coater Module PC7 represents another Hunkeler world premiere for large sheet processing. This new module fulfills two functions: primer application (pre-coating) on unprinted paper prior to the printing process or finishing (post-coating) of printed paper webs. The primer coating enables the use of ordinary offset papers on inkjet printing systems, translating into high savings in terms of paper costs, flexibility, storage and logistics. Depending on the intended use, the Primer Coater Module PC7 is integrated into the line either before or after the digital printing process. Hunkeler will provide the required consumable materials.

Highly dynamic perforating and punching

With the DP6 module, the company has developed a unique solution for integrated and highly dynamic perforating and punching. The individually driven hydraulic cylinders enable dynamic switching of punching and perforating patterns from one sample to the next. In addition to longitudinal and cross perforation, dynamic file hole punching or form punching are also possible.

The DP6 is itself modular in design. Various combinations are made possible by successively arranging up to three tools. The DP6 is ideal for application areas such as trans-promotional products with individual file hole punching, changing perforations and security punching. One example is the production of coupons combined with payment slips.

AMAZIPRO CC (+27 21) 556 1040 info@amazipro.co.za www.amazipro.co.za