Top technical teams from Dupont Cyrel and Esko gave an overview of packaging solutions at a presentation hosted by Antalis South Africa on 28 February. Dupont also outlined the exciting products it has outlined for drupa.

Dan Pulling from Esko and Jan Scharfenberg and Assuman Yazici from Dupont Cyrel each gave a presentation.

Pulling said that the Esko has made it their mission to bring out a lot of innovation with flexo. HD flexo is pushing the envelope of whats capable with flexo today, flexo can now give the same quality as offset and gravure. End customers want their packaging to be the same, they want brands coming across to the consumer to be consistent and thats what we can offer them today with flexo.

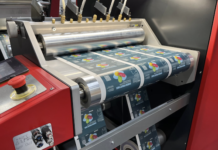

The quality of offset and gravure printing has always been somewhat of a Holy Grail for flexo. But, with HD Flexo, the gap is closed. Bringing consistency, vibrant colours and increased print quality, HD Flexo raises the industry standard in flexo printing.

Flexo printing can now compete with offset for quality labels and with gravure printing for flexible packaging. In addition, digital plate exposure ensures greater consistency in plate production and in printing.

A great deal has been developed with digital over last 8-10 years. An advantage of digital is that it provides quicker start-up times but printers cant afford to do long print runs on a digital press, they need a conventional press – this is where HD flexo comes in as it allows printers to get the quality wherever they want and choose where they want to print it, said Pulling.

With flexo, weve seen a lot happening in the last 20 years with regards to images, presses, analogues, inks, plates and exposing equipment, but flexo has always perceived to provide low quality, less consistency and more complexity. We can challenge those views because with HD flexo what we wanted to provide is a way to produce high quality graphics so customers have a product that is vibrant and stands out in the store. Weve been able to overcome the limitations associated with flexo.

The company has increased resolution on CDI, which gives a much better reproduction on very fine dots, better control in the mid-tones where the dots come together and better reproduction of fine elements. In these ways, Esko is getting flexo to compete on the same level as gravure and offset.

Another limitation associated with flexo is the highlight, so the company has developed new types of screening. Weve combined multiple dot shapes to create support for the very smallest dots on the plate, so we give support to the highlights.

Eskos solutions create value for converters and trade shops with a highly automated flexo platemaking process integrated with the prepress workflow. This helps flexo professionals to speed up production and to drive down costs. Key enabling elements include the JDF connection to the Automation Engine (prepress workflow integration), that communicates plate production data to and from production workflow and ERP systems.

With solutions for label printers and corrugated box converters, Digital Flexo Suite automates and improves various plate preparation activities in the flexo plate room and reduces plate waste by at least 15%. This high level of integration and automation serves the needs of an industry that is challenged to produce packaging cheaper, faster, better and greener.

Eskos digital flexo programme at drupa 2012 confirms its continued innovation and leadership. The company will display the CDI Spark 4835 Auto with unique digital Inline UV 2 exposure along with the CDI Spark 2530 with Inline UV and magnetic drum. It will also showcase Suite 12, software which arms the graphic arts industry for todays design, colour and workflow challenges.

Jan Scharfenberg from DuPont outlined the products the company showcase at drupa:

DUPONT Cyrel® FAST 3000 TD SYSTEM

The product ensures outstanding quality and uniformity in a larger 127cm x 203cm (50” x 80”) format, eliminating size constraints for wide-web printers wishing to benefit from solvent-free processing of plates.

DUPONT CYREL® DIGICORR

This is a modified digital workflow which produces a Digital Cyrel plate that is optimised for the needs of the corrugated printer. By imaging and processing Cyrel® DPC in the DigiCorr process, your tradeshop is able to provide a digital plate that further raises the quality bar.

DUPONT CYREL® DIGIFLOW

This new digital workflow enhancement is designed to expand the capabilities of digital Cyrel® and digital Cyrel® FAST while enabling great flexibility to create the desired dot shape plate by plate.

DUPONT CYREL® FAST ROUND 1450 FR

The sleeve making system uses dry, thermal technology to quickly process high quality photopolymer sleeves, eliminating all solvents and aqueous solutions from the plate room, and a digital Imager ESKO CDI 1450 Cantilever with a UV Inline 2 feature in flat top mode.

DUPONT CYREL® MICROFLEX MULTIPLE SLEEVE MOUNTING SYSTEM

The system allows the mounting of multiple Cyrel® Round sleeves to register on one single print adapter, increasing flexibility of the high productivity sleeve workflow.