Leading punching and loose leaf binding manufacturer Renz, has said its post drupa 2012 order intake is 50% up on the previous drupa 2008. Major highlights for Renz were the sales of several fully automatic high speed punching and binding lines, the Renz Inline 500. Two new punching and binding systems were successfully launched at this year’s exhibition, the Inline 360 and P 360 A.

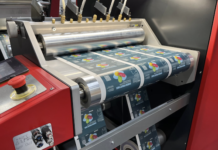

The revolutionary Inline 360 is a high speed punching and binding system, where book blocks are dropped on to the in-feed (conveyor), punched, re-collated and fed automatically into the binder. It allows for less product handling and full automation of punching and binding, a world first. The Inline is also capable of punching and binding calendar sets with either nail hole or calendar thumb cut. Once the DBW automatic cover turner is linked to the line it allows the device to automatically flip the back cover after the binding process and also spins every second book 180 degrees for level stacking. It can also be linked to shrink wrap tunnels or other boxing equipment. Great time saver aimed at high volume or fast production environments.

The P 360 A is a fully automatic modular high speed punch, with an output of up to 72000 punched sheets per hour. It has the ability to handle mixed stock including polyprop covers. Modular die insertion allows any loose leaf punch pattern to be punched. This machine bridges the gap between fully automated floor standing systems and heavy duty bench top punches, complementing the recently launched Renz wire binding machine the Mobi 360 for the book, photo book and calendar work.

These new introductions to the already successful Renz portfolio are aimed at addressing new pressures on printers, such as the print-on-demand market and calls for increased automation or inline systems, and further demonstrate Renz’s ability to continually adapt to market demands.

Michael Schubert – Renz Group CSO said, This machine, a leader in its field, reduces punching and binding bottle necks. With just one operator needed it is capable of comfortably punching and binding in excess of 1700 bound products per hour.

Daniel Pooley – Renz International Marketing Manager said of drupa 2012, In past years, customers have been more reluctant to spend, preferring to wait for new products rather than investing heavily in technology already on the market. We feel that with the launch of our new range, together with renewed confidence in the market our customers are more than willing to begin investing again.

Michael Schubert, Renz Group CSO, said, drupa 2012 has exceeded all of our expectations. It has lived up to its potential of being a selling show. There was a hugely positive air throughout and less negativity and cautiousness than we have experienced from customers in recent years.

Renz were also ecstatic about the number of demonstrations and sales of their hugely successful bench top semi automatic punching machine (DTP 340 A) and semi automatic binding machines (ECL 360 / WP 300). These machines were designed to specifically bridge the gap between full automation and traditional foot pedal punching and binding systems and it is testament to Renz’s innovation that even with the introduction of newer, more automated equipment, these machines still remain hugely popular with customers.