Muller Martini will use live demonstrations of a wide range of different printing products to show how customers will be supported on their individual journeys into the future.

They will be presenting four highly automated, industrial production lines that are integrated in the Connex workflow under the motto ‘Driving the Digital Transformation’ at drupa in Düsseldorf from May 28 to June 7, 2024.

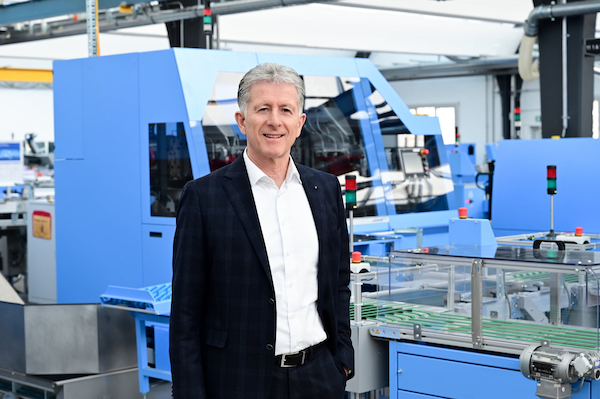

‘We use the latest equipment to demonstrate why we are capable to accompany our customers on their individual journeys into the increasingly digitalised future and how, with our solutions, they can consistently use the potential of new technologies,’ said Bruno Müller, CEO of Muller Martini.

The digital transformation offers new opportunities for both machine manufacturers and customers. ‘The decisive factor is increasingly not the individual machine, but several machines in an integrated production system. This makes the higher-level workflow, which dynamically controls the production process, an important success factor. We are subsequently well prepared to support our customers in digital transformation with our extensive range of solutions which we have expanded in a targeted manner over the years.’

The opportunities for customers lie in new product forms such as personalised content or the use of high-quality materials, but also in on-demand production, whereby storage costs or overproduction can be eliminated.

The success of a new system depends on the entire process and not primarily on the selected printing technology. Small production volumes are also possible in offset printing. Therefore, the economically viable production of short runs does not necessarily require digital printing presses, but above all an end-to-end process from prepress to dispatch.

The Connex workflow system developed by Muller Martini is a crucial driver behind the digital transformation. ‘It’s really an impressive thing if you consider the necessary functionality to dynamically map without manual intervention all variants and influences in the manufacturing process,’ emphasised Müller.

A typical Connex example is the correct page arrangement, impositioning, on the printing sheet with all the necessary marks, codes and further processing variables that need to be taken into account during further processing for a high-quality product. In extreme cases, these change dynamically from product to product. This is why Connex and its functions are the key to efficient production.

Muller Martini will be demonstrating how this works in practice at its drupa stand. Integrated in the Connex workflow are all four highly automated, industrial production lines: Antaro Digital perfect binder, SigmaLine Compact, Primera PRO saddle stitcher and Ventura MC 200 thread sewing machine. The world premiere of a Hunkeler solution at the stand also demonstrates that Muller Martini is now an even stronger partner for end-to-end solutions, particularly in the growth segment of short-run book production.

‘We offer customers a homogeneous system package with our comprehensive, modular platform that can grow with their needs,’ emphasised Müller. ‘This is how we support them as a partner on their journey to digital transformation. In doing so, we are following our claim: Muller Martini – your strong partner.’

THUNDERBOLT SOLUTIONS

+27 11 657 7000

www.thunderbolt.co.za