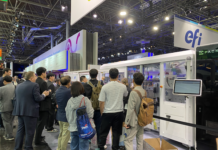

The company showcased the new Lithrone GX40 Carton for carton printing using the revolutionary H-UV system as well as the Lithrone A37, geared to the A1 market, the Enthrone 29P and two prototype digital printing presses, the Impremia IW20 and Impremia IS29.

The Lithrone GX40 Carton is a six-colour H-UV-equipped 1.01m (40-inch) sheetfed offset press with a coater for carton printing and is the ideal machine for package and special printing applications. This machine features special specifications, such as a high-resolution inspection system that is exceptionally beneficial when printing on expensive heavy stock and a roller conveyor system that facilitates the transport of heavy stock.

The press is equipped with a Fully Automatic Plate-Changing System (Full-APC) that performs sequence control to enable the fastest possible plate change, as well as a high-resolution type PQA-S that uses a two-camera system for the detection of print defects, which is a high priority in package printing. The PDC-SX on the operation console is capable of measuring special colours, which are frequently used in package production, and enables the inspection and maintenance of high print quality. The press will also have special specifications for heavy stock, such as Komori’s Non-Stop Delivery System and the Roller Conveyor System for paper transport.

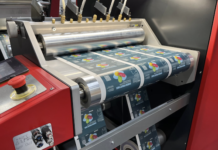

H-UV System

This revolutionary technology opens a new era for offset printing. The H-UV system works without spray powder and allows extremely fast drying using a UV lamp developed with Komori know-how and high-sensitivity UV ink. With just one lamp mounted in the delivery, this system offers high print quality and reliability as well as excellent economic and eco-friendly performance.

Job turnaround time is dramatically shorter than with conventional printing because printed items are cured instantly by an in-line process. UV curing is extremely effective in shortening the time from receipt of materials to delivery because finishing work such as cutting, die cutting and folding can be performed immediately.

Since there is no waiting for printed items to dry as required with conventional printing, a large stock space for printed work is not required. The stock space necessary to accommodate the increasing number of short runs of varied items can be reduced.

Since the entire printing process is powderless, the plant has none of the troubles associated with the scattering of powder granules. The surface of printed items is smooth, which makes surface processing in post-press very easy. Also, since the problems resulting from supplementary printing by an on-demand press can be reduced, UV curing can facilitate more orders in applications that require no adhesion of drying powder. The elimination of the dry down phenomenon also makes it easier to check quality.

Lithrone A37

This four-colour 0.93m (37) sheetfed offset press is a high performance, cost effective machine and is designed to be a pressroom workhorse. It comes equipped with Komori’s basic Lithrone S Series features.

Enthrone 29P

This is well suited to production of a wide range of work in short runs with stable print quality. With its ergonomic step-less operator-side design and small footprint, the Enthrone 29 fits easily in any installation space. It is a machine offering working efficiency that ensures higher margins and solid growth. By performing changeover between light and heavy stocks on both machines, the demonstration will exhibit printing efficiency, the ability to handle a wide range of work, and high print quality.

The company showcased its two prototype digital printing presses, the Impremia IW20, a newly developed four-colour 51cm (20) web-fed inkjet digital printing machine which has a maximum resolution of 1200 dpi (switchable with a 3-mode system) and a maximum printing speed of 150 m/min (switchable with a 3-mode system), as well as the Impremia IS29, the four-colour 74cm (29) sheetfed inkjet digital printing system with a maximum resolution of 1200 dpi and maximum printing speed of 3300sph.