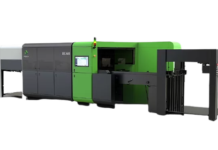

As with many commercial print companies, Tony Bowyer Print had been seeking ways to generate new business through their established customer base and to grow their dynamic design-focused print-based products into new markets. After carefully considering all the options available, they invested in an Intec SC5000 digital sheet die-cutter and creaser to enable them to take their work to a new dimension.

The company has seen a significant increase in new business since their decision to acquire their Intec ColorCut SC5000 digital sheet cutter. Having taken delivery and set up their new SC5000 in the morning, an enquiry for door hangers, cut to a bespoke shape, came in at midday. The team had only expected to start getting familiar with the device in the afternoon, but in actual fact they ended up proofing and pricing the job within the hour, gaining approval to produce 500 hangers, which they printed and cut all to shape for delivery the very next morning. The client was delighted and has since returned for several new orders.

‘Fortunately, the SC5000 is super easy to use and works alongside the existing software we have expertise in, so the SC5000 really complemented our in-house design and print philosophy,’ said Lee Bowyer, company partner. ‘This, backed up by the training Intec provided, helped us find the SC5000 to be exceptionally easy to use, so it was actually a very simple process to achieve.’

Another new business stream that has evolved since having the facility of the SC5000 is pre-production prototyping. A UK manufacturer of Christmas crackers and other celebration novelties, has found that having Tony Bowyer Print trial their proposed cutter shapes in low volumes on the SC5000, provides an extremely cost-effective, accurate and fast option for prototyping designs before committing to massive offset production.

A key factor when deciding to purchase the SC5000, was the automation. ‘We are a busy print shop with tight turnaround times for our clients. So one concern we had with any new equipment, was – ‘Who will need to run it, and how much time will it take?’ However, the SC5000 is an automated cutter with an automatic feeder that can stack up to 900 sheets of media. And because a QR code is added to every job using the ColorCut software, the cutter can work unattended. All I need to do, is load the sheets and walk away. From a production point of view, this is about as easy as it gets.’

This in-house advantage and rapid turnaround proved its weight in gold when a valued customer needed bespoke labels for an impending launch event, and to their horror discovered that their usual packaging label would no longer stick to their new packaging bags. It turned out their newly sourced white bags had a non-stick quality and would require a special, extra strong adhesive label.

Tony Bowyer Print had the answer, with the SC5000. Because we had all the kit in-house, they were able to check which of their adhesive products gave the best adhesion to their clients’ new style bags, then design, print and cut their customised labels that day, enabling them to still make their launch event with time to spare. They could never have achieved, or even offered this, if they had been at the mercy of outsourcing timescales imposed by third-party suppliers.

Since investing in the new Intec SC5000 digital die-cutter, the company is discovering many new business opportunities. The SC5000’s capability to create prototypes and short runs, on-demand with tight turnarounds, or even be part of the initial brain storming process, when a client is discussing ideas, has created undeniable credibility and delivered a sense of professionalism that the company is very proud of.