In this article, Focus Label Machinery unpacks the meaning of the term ‘hybrid printing, and how a label and packaging business can benefit. Essentially, hybrid printing is a method that combines two established printing techniques into a unified strategy – in this instance flexographic or flexo printing, and digital printing.

Flexographic printing is historically the go-to method for high volume packaging, labels and textile print businesses because of its reliability and cost effectiveness in volume, whereas digital printing offers businesses and their clients far greater flexibility, faster changeover times, and personalisation opportunities, making it perfect for producing small batches and variable designs.

By integrating these two approaches with converting and finishing the users gets an extremely versatile printing and finishing platform that delivers the speed and efficiency of flexographic printing with the adaptability of digital. This equips a business to meet a wider range of emerging market needs without compromising production times or quality.

Due to recent improvements in technology the big benefit of flexographic printing is its consistent quality over long print runs, making it ideal for large-scale production and repeat projects. However, this standardisation frequently comes at the expense of customisation and scalability. Short print runs and runs that need frequent adjustments can be costly when using a flexographic press due to the setup and plate making costs. Digital technology cuts out the need for plates, enabling users to accommodate shorter runs and variable data more effectively.

With a hybrid solution, users can switch between these two modalities seamlessly, giving them the ability to, for instance, produce thousands of preprinted labels as they would with a flexo press, but using digital heads to apply unique details, messages, or promotional code to sections of the print run.

A true hybrid solution will include converting and finishing in the same pass, for example, over varnish, spot varnish, over Laminate, embossing, die cutting, foiling and embellishment.

Hybrid printing has a variety of applications for print management companies, providing precision, efficiency, and flexibility. For example:

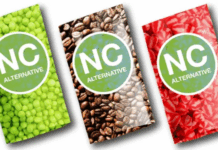

- Food & drink packaging: customers often require vibrant, durable packaging for food and beverage products that communicate safety and freshness while meeting UK and EU regulatory requirements. Hybrid printing gives users the flexibility to produce large-volume print runs with the same cost effectiveness of flexo, while customising nutritional information or adding promotional codes to some labels through variable data printing.

- Cosmetic and healthcare product labelling: hybrid printing solutions open a range of print finishing possibilities to reflect the luxury and intricate detail often required for cosmetic and health products. Alongside variable product information tailored for different sectors, print runs can include metallic finishes, gloss varnishes, and other finishes to meet your customer’s needs.

- Label and packaging printing for consumer products: hybrid printing lets you produce cost effective promotional and seasonal packaging and label printing with the ability to incorporate local promotions, limited edition designs, and QR codes within the print run without significantly impacting costs and set up time.

FOCUS LABEL MACHINERY

https://www.focuslabel.com