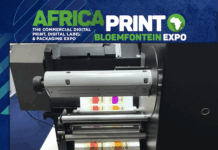

This next-generation Truepress LABEL 350UV SAI-S press brings several performance improvements, including faster 60m/min production speeds, automation and workflow integrations in collaboration with leading finishing equipment providers, and compatibility with upcoming SCREEN inkjet innovations and improvements. As part of the Docuworld Group, the largest Spanish industrial group in the packaging and labelling sector, Rever has consistently expanded its printing capacity, with the latest SCREEN Truepress LABEL 350UV SAI-S press marking the fourth machine of its kind at Rever and the fifth within the Docuworld Group.

The adoption of digital printing posed initial challenges for Rever’s customers, many of whom were accustomed to traditional flexographic direct colour printing compared to the first generation of inkjet machines that only had four colours (CMYK). However, the transition to SCREEN’s inkjet technology offered significant benefits, including faster delivery times, the ability to handle short-run jobs, and an overall improvement in label print quality as the colour gamut of digital inkjet improved to directly rival analogue printing.

Rever’s early adoption of digital printing quickly paid off, with the company acquiring a second SCREEN press just one year after the first installation. To their team advantages were clear from the start. The consistency of colour from the first to the last label, combined with the reliability of the equipment, made a compelling case for them to continue expanding their digital printing capabilities.

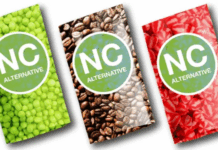

The new press also expands the already broad colour gamut with Truepress LV02 Ink adding vibrant Orange and Blue inks to the already vivid CMYK, to cover a wider range of hues while extra high-density white ink provides a thorough base coverage for clear and plastic label films, ensuring that the increasing demanding colour expectations will continue to be met. This expanded colour capability not only improves visual appeal, but meets new more stringent regulatory requirements for consumer safety, making it an ideal solution for multinational corporations, particularly in the pharmaceutical industry.

This advanced colour gamut can be achieved consistently due to SCREEN’s EQUIOS workflow and colour management software. These tools ensures that the presses printing output can meet expected Pantone targets without increasingly scarce skilled analogue press operators from the very first label of a production run to the last and even repeat jobs months later.

Considering the future of their partnership and forecasts for the Spanish printing market, Rever is committed to continued growth by adding new innovative digital printing equipment and expanding their label offering to meet our clients’ evolving needs. From the first press they have come to trust SCREEN’s the ongoing commitment to continue to guide and develop this exciting new technology and to push the boundaries of label printing quality, colour gamut, and print consistency. Together with Docuworld Group, they are aiming to provide cutting-edge label solutions that anticipate future demands with SCREEN’s reliable digital printing solutions.

ROTOCON

+27 11 397 2172

http://www.rotocon.world