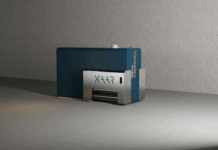

The Pack Druk company has been producing packaging since 1958 and is currently a supplier of packaging to large pharmaceutical corporations and others throughout Europe. The company recently installed a new Komori Lithrone GL-640A HC press, which complements their existing fleet of presses. This is the second machine of this type installed at the plant in the last two years.

These machines are now central to their high-volume, high-precision jobs. The GL-640A HC uses less material, such as ink and paper, which leads to cost savings. Its compact size takes up less physical space, making it ideal for the company’s needs. The machine’s lower energy consumption contributes to sustainability, while its advanced automation features enhance efficiency and productivity.

As a family-owned company, Pack Druk emphasises close cooperation and partnership with clients. They don’t just print and produce folding boxes; they consult, advise, and work closely with clients to achieve mutually satisfying results. Their agility in production and investment in cutting-edge technology give them a competitive edge.

The cooperation with Komori began in 2007, when the first machine was purchased. Over the course of this 18-year partnership, the machine park has gradually expanded to four Komori machines. In the last two years alone, two of these Komori machines have been replaced with the latest GL-640A HC models — marking the second major investment in new presses in recent years.

The partnership with Komori is a key part of Pack Druk’s long-term strategy. The company sees its equipment provider not just as a vendor, but as a strategic partner whose innovations, training, and support directly impact production quality and efficiency. This close collaboration has helped Pack Druk remain competitive and forward-thinking within the industry.

Reprograf Grafikus, the distributor, played a crucial role in facilitating the acquisition of the latest machines. Their expertise and support were instrumental in ensuring a smooth installation and integration process.

‘We are proud to support Pack Druk in their journey towards innovation and efficiency,’ said Marcin Kołatko, Komori Product Manager from Reprograf Grafikus. ‘Their commitment to quality and adaptation to change aligns perfectly with our values.’

‘We are enormously proud of the sale of the GL-640A HC to Pack Druk,’ said Michal Obdrzalek, Regional Sales Director at Komori. ‘This machine offers a cost-effective solution that enhances efficiency and sustainability. Pack Druk’s recognition of these benefits underscores the strength of our business partnership and their commitment to adapting to change.’

Before selecting Komori, Pack Druk faced challenges with print consistency, downtime, efficiency, and make-ready times, especially with complex or colour-critical jobs. After evaluating other leading brands, Komori stood out due to its reliability, automation features, and robust support network. The press offered the best balance of performance, speed, and energy efficiency.

The new Komori press has made a significant impact on Pack Druk’s operations. The plant manager is impressed with the machine’s efficiency and stability, while operators appreciate its user-friendly interface and reduced setup times. Customers have noticed improved colour accuracy and faster turnaround times, strengthening their relationships with Pack Druk.

The choice for Komori has provided Pack Druk with substantial long-term benefits. The company has been able to maintain high standards of print quality and efficiency, thanks to the reliability of Komori machines. The reduced maintenance requirements compared to other brands have also been a significant advantage.

The partnership with Komori has fostered a sense of family and collaboration. The service provided by Komori is accessible and dependable, with a local presence in the Netherlands that offers direct support. This has contributed to a strong and enduring relationship between Pack Druk and Komori.

Pack Druk values the support they receive from Komori’s service team. The promptness of the support, the expertise of the technicians, and proactive maintenance planning give Pack Druk confidence that their production lines will keep running smoothly.

Looking ahead, Pack Druk’s focus is on smart growth. Negotiations are underway regarding the purchase of additional machines. The company aims to expand its service offerings, particularly in sustainable packaging and value-added printing. Technological innovation and environmental responsibility will remain central to their strategy.

THUNDERBOLT SOLUTIONS

+27 11 657 7000

www.thunderbolt.co.za