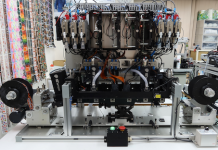

Megnajet has developed a new fluid management system designed for wider multi-printhead inkjet applications, expanding its high-volume JetSource product range. To address the demands of OEMs and integrators for large-volume, high-duty applications, the new JetSource HFR features a two-litre fluid volume and an increased number of printhead inlets and outlets to maximise productivity.

The ability to deliver a continuous supply of fluid makes the JetSource HFR ideal for any high-productivity, high-duty printing, including label, web, roll-to-roll and scanning applications. Following the launch of Megnajet’s JetSource Core system in 2023, which accommodates up to five independent fluid paths. The JetSource HFR can support six to eight, making it ideal for users with bar-based systems or wider application requirements for up to 4 litres of recirculation.

With over 900 watts of heating power, the JetSource HFR quickly reaches the desired temperature, leading to fast start-ups. Its dual heating and sensing features ensure temperature regulation for high-quality printing regardless of duty cycle. And its bar-level internal bypass mode allows for the full fluid volume to be recirculated and heated throughout the full system. Maintaining reliability, the new system provides pressure stabilisation and fast responses to changes in print duty. This is achieved with the venturi meniscus control used across the JetSource range, ensuring consistency when ejecting large volumes of fluid.

The launch of Megnajet’s JetSource Core and the new JetSource HFR fluid management system allows OEMs to harness the benefits of high-productivity printheads and printbar-based architecture.

Mike Seal, General Manager at Megnajet, stated: ‘We developed the JetSource HFR to address our customers’ needs for precise fluid control and conditioning for high-productivity applications. This enables OEMs to focus on their core operations, without having to invest time and resources in developing their own systems.’

MEGNAJET

www.megnajet.com