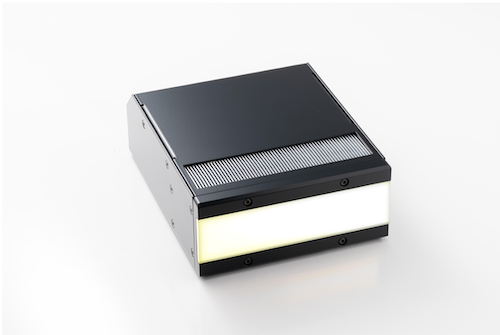

The new air-cooled, UV LED G7A Series light source provides revolutionary curing performance for applications such as ink, resin curing and adhesion. It offers a customisable irradiation width to suit a wide variety of printed materials and stable operation, which is enabled by monitoring functions for irradiation status.

Kyocera’s UV LED light sources not only have a low environmental impact but also adopt an air-cooled system that does not require cooling water, even with high output. As a result, additional equipment such as a water-cooling system is unnecessary, enabling a more compact installation. Through this, the product contributes to greater efficiency and reduced environmental impact for various devices used in manufacturing sites, such as printing, adhesion, and liquid gasket.

It achieves the highest irradiance in its class (among air-cooled UV LED light sources for UV curing applications; Kyocera research, March 2025). By using Kyocera’s proprietary ceramic substrate with heat-dissipation as well as a module heat dissipation design that includes a heat sink, the company have maximised energy efficiency while achieving an irradiance of 20W/cm² (at 0 mm irradiance distance), the highest among air-cooled UV LED light sources in this class. Additionally, by achieving a total dose of 400 mJ/cm² at 50 m/min, which is an important indicator of curing performance, they have achieved high-speed curing performance comparable to water-cooled UV LED light sources, all within a compact design.

Compared to the conventional high-output G5H Series, the G7A Series has a footprint 62% smaller and a 10% lower height, placing it among the world’s most compact (120 x 52 x 151mm) UV LED light sources with the same optical performance. The G7A offers a 30mm irradiation window, contributing to space savings while preserving high curing performance.

The G7A has a scalable structure in 120mm increments, allowing the irradiation width to be adjusted from a minimum of 120mm to a maximum of 2,400mm, by connecting multiple light source units. This enables flexible customisation of the irradiation width to suit a wide variety of printed materials. Further, the system can connect to external devices via serial communication, permitting fine adjustments to the LED irradiation width in increments of approximately 30mm.

The G7A Series features monitoring functions via serial communication, allowing for LED temperature, LED current, fan operation time, and accumulated LED lighting hours. It can detect lighting and system errors, and provides notifications for filter replacement and LED lifespan, ensuring stable system operation.

KYOCERA

https://global.kyocera.com/