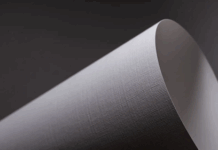

Engineered as part of EMT’s evolving Vira modular platform, the new Vira Shape Advanced Die-Cut Postcard Sheeting System enables custom-shaped postcard production across a wide range of run lengths, from short, targeted micro-runs to sustained, high-volume production. This happens at speeds up to 152.4m (500 feet) per minute, while maintaining flawless registration, precise cut quality, and consistent performance. The solution has been designed to help commercial printers and direct mailers meet the growing demand for high-volume, premium-quality postcards.

‘Direct mail is experiencing a resurgence, but mailers are under pressure to deliver more distinctive pieces at higher volumes,’ said Mike Herold, Vice President of Sales and Marketing at EMT. ‘This solution gives our customers the ability to stand out creatively without sacrificing speed, quality, or efficiency.’

The system’s advanced die-cut technology eliminates white edges on full-bleed dark prints and supports a wide range of formats including loyalty cards, retail promotional pieces, door hangers, table tents, tear-away designs, and uniquely shaped postcards.

Key capabilities include: superior quality output with precision die-cutting and tight web register control; custom shapes and perforation patterns for high-impact creative applications; flexible die plates for fast job transitions; simple, compact design built for 24/7 production environments; short web path to minimise waste and improve efficiency; shingle-stream delivery for seamless downstream processing; stacking options available.

‘This technology opens the door to shapes and designs previously unavailable at this level of throughput, while also giving customers the flexibility to economically produce everything from highly targeted micro-runs to millions of postcards per month,’ added Herold.

The system is available now and can be configured with other Vira modules.

EMT INTERNATIONAL

www.emtinternational.com