The 2025 European Federation of Corrugated Board Manufacturers (FEFCO) Technical Seminar, which took place at the La Nuvola Rome Convention Centre during 8–10 October, brought together producers and suppliers from the entire value chain of corrugated packaging production. The event was a key opportunity for BOBST to demonstrate its commitment to shaping the future of packaging production.

BOBST participated in two panel discussions across the event programme. CEO Jean-Pascal Bobst joined Marco Bertola (Fosber Group CEO), Lars Engel (BHS Corrugated Managing Director), and Markus Weiss (Koenig & Bauer CEO) to debate the topic of data, services, safety and more under the headline: ‘Supporting Operations Through Remote Expertise, Service Innovation and AI’.

BOBST CTO Léonard Badet took part in a discussion on collaborative approaches between users and suppliers, together with Sebastian Schieder, BHS Corrugated and David Giusti, Fosber Group, and moderated by Health & Safety Committee Chairman John Nicholls, Smurfit Westrock.

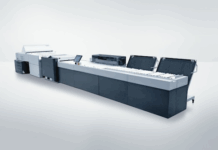

Other presentations came from Allegra Alessi, Product Manager IoT, who spoke about BOBST’s strong expertise in energy monitoring, highlighting BOBST Connect’s advanced data collection and analysis capabilities when deployed on flatbed die-cutters, inline or on folder gluers machines. Product Marketing Manager Aurelie Gasiglia won the award for Best Presentation at the event for her talk about the new BOBST U PACK solution, which unlocks the full potential of DRO machines. She outlined some of the new features set to be fully unveiled in 2026. These extended functionalities will significantly increase capabilities and agility, giving converters exceptional advantages in allowing them to deliver premium packaging more efficiently.

Also looking to the future, Virginie Dubois-Guignard, Marketing and Communication Manager Folder-gluers and Robotics, offered an exclusive look at a new generation of multi-point folder-gluers designed to elevate safety, automation, and connectivity in packaging production. Presented as part of a fully integrated line with robotic feeding and palletising, this innovation marks a major step forward in reshaping industrial performance, by enhancing safety, simplifying operations, and boosting efficiency.

Finally, Product Marketing Director Christian Vionnet spoke on the topic of ‘Innovating for eco-friendly productivity’. He presented the BOBST Connect Data Kit, an eco-smart solution for BOBST ETERNA die-cutters and other machines (any brand, any age) that tracks energy use and boosts productivity through real-time data insights. This new product is a universal, sustainable, and performance-driven solution fully integrated with BOBST Connect.

‘BOBST strong participation at the FEFCO Technical Seminar covered all four cornerstones of our vision: automation, connectivity, digitalisation, and sustainability. These are the pillars on which we are building a successful future for the packaging industry,’ concluded David Arnaud, BOBST Product Marketing Director. ‘We not only showcased the latest industry-leading innovations from BOBST already on the market, but also outlined the exciting developments that are about to be unleashed.’

BESWICK MACHINERY – BOBST AUTHORISED AGENT SOUTHERN AFRICA

+27 11 433 2686

bmmarketing@beswick.co.za

www.beswick.co.za