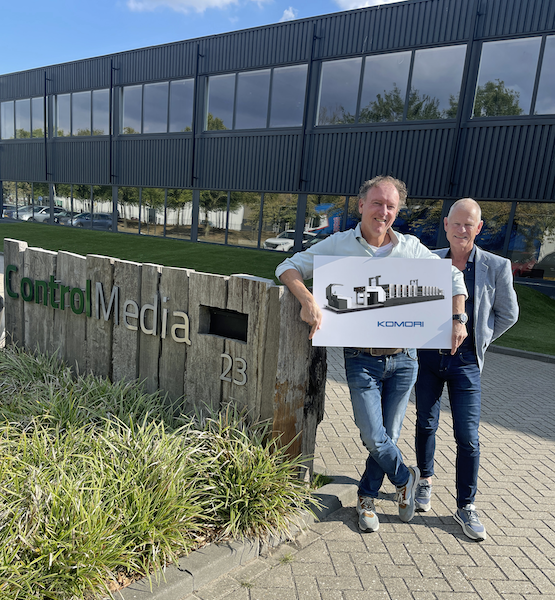

A new Komori GL-1040P advance ten-colour offset printing press in the 70 x 100cm format will be added to Control Media’s print hall, where three German offset presses are already in operation. Control Media made the switch after careful consideration.

‘We thoroughly explored the new possibilities offered by modern offset presses,’ said Managing Director, Leon van Nunen. ‘At Komori, they listened to us very attentively. We visited the factory in Japan several times and spoke extensively with fellow printers who already use Komori presses. Given that presses in this category are almost identical in terms of cost-efficient productivity and output, the finer details become decisive. Personal relationships and trust also play an important role.’

‘We immediately had a good connection with the professionals at Komori, and we’ve had an excellent working relationship with AtéCé, Komori’s dealer, for many years,’ Van Nunen explained. ‘That certainly influenced our decision.’

In addition to being a supplier of graphic consumables, AtéCé is the exclusive dealer of Komori offset presses in the Netherlands. The company is also the exclusive distributor in the Benelux and Germany for CRON CTP systems and flexo plate exposers, AGI flexo plate processors, Quicker flexo cleaning equipment, and JWEI digital cutting solutions.

Van Nunen continued, ‘We chose a ten-colour press to print on silk paper with a coating layer. This prevents smudges and scuffing, allowing us to finish the printed work immediately — and it’s more cost-effective than LED-UV, which we’ve now phased out.’

‘Our new Komori is fitted with an Autopilot system, which sets up new jobs fully automatically. During printing, the Autopilot continuously monitors the entire process, so the operators no longer have to intervene manually. It’s efficient and helps to avoid errors.’

‘The Komori also runs with KP-Connect,’ he added. ‘This advanced software tool is indispensable for operators during the printing process, particularly when it comes to quality control. With KP-Connect, file errors are detected straight away, which helps prevent waste.’

‘As a cloud-based solution, KP-Connect makes operational data available in real time — both on the production floor and within management information systems. All these modern features contribute to making the printing process more efficient and the output as high as possible.’

THUNDERBOLT SOLUTIONS

+27 11 657 7000

www.thunderbolt.co.za