Tecnau, in collaboration with its local distribution partner Fellowes Beswick, developed a custom solution to meet a South African educational department’s evolving needs. For years, the department relied on a robust digital print production system to supply schools with educational materials, booklets, and exam documents. But as the demand for flexibility in print applications grew, they sought to expand beyond booklet production into broader commercial print and graphic arts applications.

Rather than investing in an entirely new system, they went back to Tecnau for an upgrade that would allow them to enhance their capabilities while maintaining their existing infrastructure.

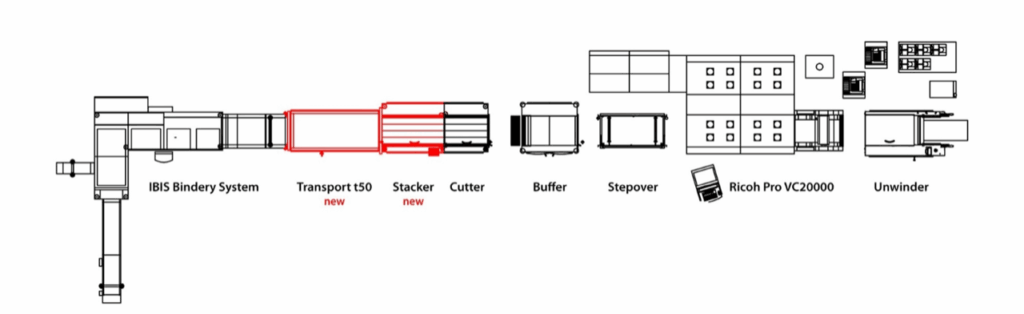

Their original system, a Tecnau Roll-to-Cut-Sheet Series 20, was designed for high-speed booklet production. It included an unwinder, cutter, and a Transport t20 unit that delivered single sheets directly into an IBIS Smart Binder for stitching. While this setup provided reliable booklet production, it lacked the versatility needed to handle a wider range of applications.

To expand production capabilities without unnecessary costs, Tecnau introduced two important upgrades to the system:

– Stacker s20: this new module allows for stacking sheets in 1-up, 2-up, and 3-up configurations, enabling the production of materials beyond stitched booklets, such as brochures, posters, and loose-leaf educational documents.

– Transport t50: replacing the previous Transport t20, the Transport t50 system offers dual functionality. It can either transport single sheets to the IBIS Smart Binder for booklet production or operate as a standard conveyor, delivering stacked sheets for non-booklet applications. This level of flexibility is typically found in Tecnau’s Revolution 50 series, but it was specially adapted for their Series 20 setup, marking a unique integration effort.

‘The Transport t50 offers significant flexibility by allowing both single-sheet delivery to the IBIS Smart Binder and stacked output on a conveyor. This enables them to diversify its production, serving a broader range of printing needs,’ said Thomas Olofsson, Tecnau Area Manager.

This upgrade was made possible thanks to the partnership between Tecnau and Fellowes Beswick. The complete system was installed inline with a Ricoh Pro™ VC20000 series high-speed inkjet press, ensuring perfect operation from roll to finished product. Fellowes Beswick played a key role in coordinating the installation, leveraging its long-standing relationship with Ricoh to ensure smooth integration.

‘Working with them on this upgrade has been a fantastic opportunity. Our more than 20-year partnership with Ricoh in South Africa allowed us to collaborate seamlessly, bringing the right expertise and understanding to the project,’ said Brandon Jordaan, Print Finishing and Export Sales Manager, Fellowes Beswick.

With the upgraded system in place, they can now produce a wider variety of materials while maintaining their staple booklet production. The enhanced setup has delivered tangible benefits:

– Increased production versatility: the ability to handle both booklets and commercial print applications.

– Cost-effective enhancement: rather than purchasing an entirely new system, they achieved their goals through strategic upgrades.

– Smoother workflow: the Transport t50’s flexibility ensures efficient switching between booklet production and stacked output in no time.

This successful installation underscores Tecnau’s commitment to providing tailored automation solutions that align with customer needs. By listening to their requirements and leveraging strong distributor and partner relationships, Tecnau delivered a solution that enhances production today while ensuring scalability for tomorrow.

FELLOWES BESWICK

brandon@beswick.co.za

https://fellowesza.co.za/