South Korean company Sambo Corrugated Board has invested in the MASTERCUT 1.7 line from BOBST. The MASTERCUT 1.7 Autoplaten® die-cutter provides the highest productivity and best possible product quality, incorporating pioneering solutions that deliver higher running speeds, fewer stops, shorter make-readies, and matchless quality.

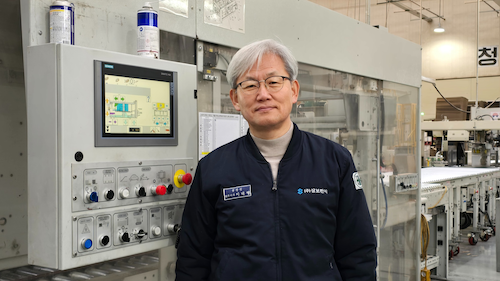

‘We chose the MASTERCUT 1.7 because of its reputation for fast speed, precise standards, machine accuracy, and durability,’ said Daiyoung Lee, Senior Managing Director at Sambo Corrugated Board, ‘It will help us to reduce defect rates and enable faster production, improving delivery times and fostering greater trust and satisfaction among customers.’

Sambo Corrugated Board has invested in a full production line, which incorporates fully automatic loading with the BOBST LOADER AF, flatbed die-cutting with the MASTERCUT 1.7, precise stacking with the BREAKER 2 FLAT TRACK, and automated palletising with the PALLETIZER 2.1.

Highly automated and easy to operate, the production line reduces the need for skilled operators. The MASTERCUT 1.7 features an intuitive human-machine interface (HMI) with setting and display of all production parameters and job data storage.

‘This investment will help us to navigate through the ongoing chronic manpower shortages,’ said Lee. ‘We anticipate that the new line will help us reduce costs, secure more orders, and deliver high-quality products efficiently while requiring less manpower.’

As South Korea’s largest specialised company in corrugated cardboard and boxes, Sambo produces a wide range of products, including packaging for food and beverages as well as for the e-commerce market. The partnership with BOBST sees the union of two vastly experienced leaders in their fields, both with a firm dedication to quality.

‘We chose BOBST because of its strong global reputation, the expertise of the sales force, and the assurance of prompt after-sales service,’ said Lee. ‘Long-term reliability was also a critical factor. We expect cutting-edge functionality, high precision, and trouble-free operation from BOBST’s flatbed die-cutter equipment. Additionally, the machine’s durability aligns with our commitment to produce quality products sustainably over the long term.’

BESWICK MACHINERY – BOBST AUTHORISED AGENT SOUTHERN AFRICA

+27 11 433 2686

bmmarketing@beswick.co.za

www.beswick.co.za