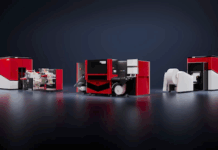

At an open house in April, held at the San Giorgio facility in Italy, BOBST showcased its portfolio for flexible packaging production, demonstrating the latest value-adding innovations in printing and converting. Working closely with partners to create collaborative solutions, BOBST leverages its local Competence Centers to drive global advancements in packaging.

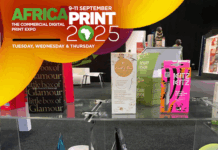

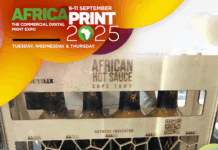

BOBST welcomed visitors across two days, on April 8 and 9, offering machine demonstrations, presentations and networking opportunities with senior leaders and other industry experts. Live demonstrations of BOBST’s innovative smartGRAVURE solution shown on a MASTER RS 6003 press was the highlight on both days.

Offering the ultimate in optimisation, smartGRAVURE is an end-to-end digitalised process that allows converters to deliver exceptional and consistent quality, with very low waste of substrates and inks. The system leverages automated process colour management with BOBST oneECG (Extended Colour Gamut) printing, which incorporates single-touch oneSET automatic setup using the Job recipe management system for data connectivity via the BOBST Connect cloud-based platform.

Showcasing BOBST’s lamination expertise, the solventless NOVALAM S 550 laminator was presented in full production mode throughout the two days. This cost-effective, compact machine impressed with its agility in processing the latest trending materials, including very thin, stretchable films and metallised films. Simple to implement with ‘plug and play’ installation, it is available in three standard web widths, with other widths available as option, and runs at a maximum lamination speed of 450m/min; a real must-have for converters of any size.

The comprehensive programme also presented a group of key technology and process partners covering other aspects of flexible packaging production. They included Advanced Vision Technology (AVT) for inspection and print process control systems; Belgian packaging consultancy firm Co-ëfficiënt; Sun Chemical, manufacturer of printing inks, coatings and adhesives; lamination specialist Synaptik from Spain; and substrates and media manufacturer UPM Speciality Papers.

BESWICK MACHINERY – BOBST AUTHORISED AGENT SOUTHERN AFRICA

+27 11 433 2686

bmmarketing@beswick.co.za

www.beswick.co.za