Taiyosha Co., Ltd. — a long-established Japanese printing company with an 82-year history — specialises in educational books, reference materials, business biographies, dictionaries and exam guides. A shortage of skilled workers and the need to improve cost efficiency are two main challenges the printing industry faces. Finding personnel has become increasingly difficult, affecting production and service quality. At the same time, companies struggle to reduce costs and streamline operations, often dealing with too many manual touchpoints. Taiyosha also faced these challenges, compounded by an aging workforce.

President Shigenori Daido had already taken steps to diversify the company beyond printing for the educational market, expanding into new ventures such as PR services, event planning and programming classes for children. However, he recognised that it was also essential to modernise its core printing operations to secure the company’s future.

Tomoyuki Hori, General Manager of the Prepress Division, partnered with ECO3 to automate Taiyosha’s plate-making. Annually they produce 90,000 Energy Elite plates using two Avalon N8-90 CtP systems.

‘The challenge was handling five plate types with different punches from our two ECO3 CtP systems. We needed a solution that could manage this complexity while reducing manual work.’

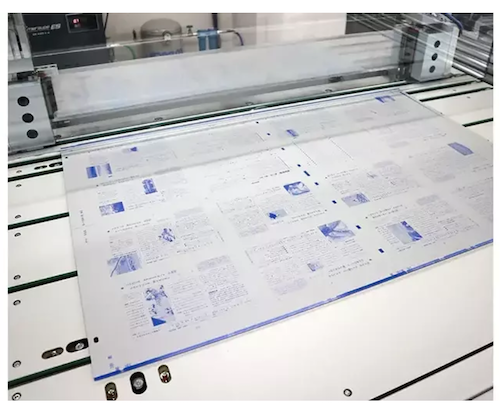

With ECO3’s support, Taiyosha implemented the Plate Transportation System (PTS), streamlining plate handling and boosting efficiency. In this automated workflow, the Apogee prepress system adds QR codes to each plate. Plates imaged by the two CtP systems are merged onto a single transport rail. The QR codes are scanned to determine the correct punching and bending requirements. BEIL Systems punch benders take care of this. Job information is then printed on each plate’s back using an inkjet printer. Finally, the plates are sorted onto 10 stackers, ensuring that front and back sets are correctly grouped for easy transport to the corresponding printing presses.

With PTS in place, Taiyosha reduced manual touchpoints by 80% and cut the number of prepress operators from five to two. Yamazaki Shota, Deputy Manager of the Prepress Division, summarised the impact of the new system, ‘Previously, punching and bending often required overtime or carried over to the next day, even when plates were prepared on time. Now, everything is completed within working hours, with no scratches or delays. The system has successfully reduced labour, work hours and plate issues.’

However, further automation opportunities remain. Adding an Expert Loader — an automated CtP pallet loading system with a 1200-plate capacity — to the second CtP system could further streamline plate handling. Additionally, automating imposition within the Apogee workflow would enhance efficiency.

ECO3 SOUTH AFRICA

+27 11 921 4650

dave.reynolds@ECO3.com

http://www.eco3.com